Reformation of printing and dying sewage with Goldsmith Line (Shenzhen) Co., Ltd.

Bright spot

The original coagulant sedimentation tank was abandoned in system reform, saving 300 thousand yuan of the original monthly cost and avoiding secondary pollution.

Coats Line (Shenzhen) Co., Ltd. is a subsidiary of British Coats Group in. Its main products include sewing thread, embroidery thread and zipper. Wastewater treatment in this project belongs to mixed sewage of printing and dyeing wastewater and a small amount of domestic wastewater. The water quality is characterized by high COD concentration, insufficient nitrogen and phosphorus nutrients, and poor biochemical property.

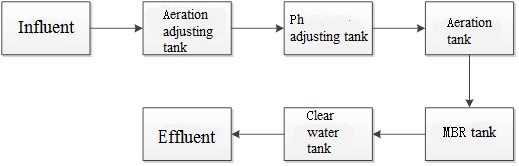

The maximum processing capacity of the system is 2800t/d. After transforming, the system abandoned the original coagulation sedimentation section. After homogenization and pH adjusting, wastewater drained into the aeration tank. This transformation can save 300 thousand flocculation cost for customers, reduce the original disposal cost of physical and chemical sludge effectively, and avoid secondary pollution at the same time. The specific process flow is as follows:

The flow chart of wastewater treatment in Coats Line Industry

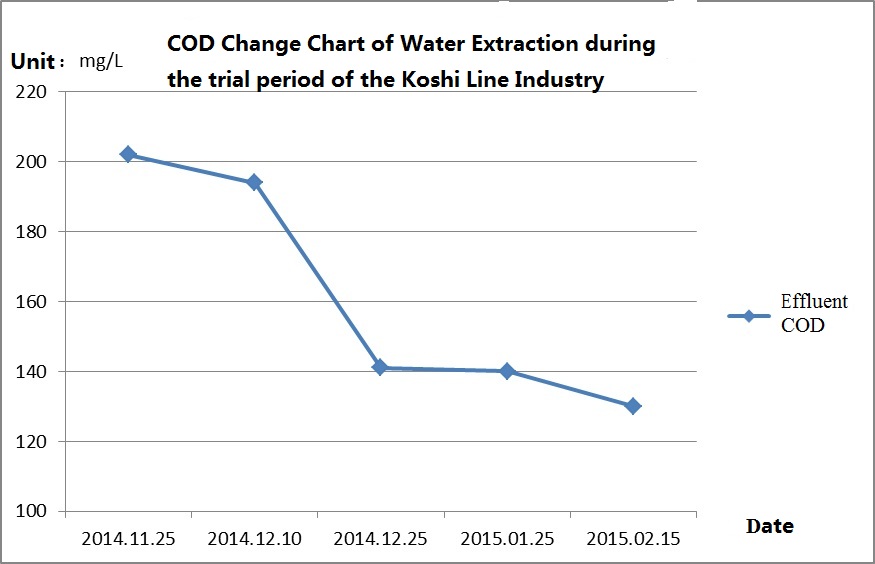

After the system transformation, our company debugged the system by adding Bio-Form® splitting agent and SF bacteria agent, which enabled the biochemical section to run steadily and the effluent can meet the standard of discharge and discharge stably.