Reconstruction project of food processing sewage treatment system with AIPU FOOD Industry

Bright spot

① With Bio-Form biofilter treatment technology as the core reform form, wastewater treatment system transformation of Shanghai Aipu Food realized the advantages of small area, low energy consumption and high impact resistance;

② The removal rate of circulating COD is 99.8% and ammonia nitrogen removal rate is 97.5%;

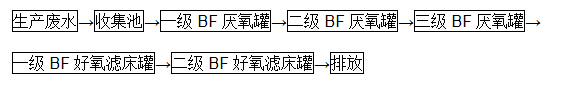

Shanghai's Aipu Food Industry Co., Ltd. is a global-oriented manufacturer of new food additives and condiment, specializing in the production of Food flavoring and freshening agent, caramel color andcooking type flavoring products. In order to realize the harmonious development of economy and environment, Shanghai Aipu's original wastewater treatment system cannot met the needs of treatment, and now it needs to be reformed and upgraded. The wastewater produced in Aipu is mainly wastewater in the process of production, ehose amount reaches 3m3/d. The following is the process flow after modification:

Flowchart of wastewater treatment process

On-spot photos

This project chooses the transformation form centering on Bio-Form biofilter treatment technology. The process from the traditional activated sludge process and biological contact oxidation method and the advantages of the improved and become a new type of highly efficient biological treatment process, cover an area of an area small, low energy consumption, high processing efficiency, high impact resistance, water stability, etc. For the properties of wastewater, the added strains include: AD agent, DW agent, MAS agent, Bio-Form® hydrolyzed acidifier, Bio-Form® decontamination, Bio-Form® nitrification, Bio-Form® cracking. The following is the water quality in and out after the system upgrade and transformation:

Table 1 Water quality of inlet and outlet water after transformation

|

|

pH |

COD |

Ammonia nitrogen |

|

Actual water quality |

5-7 |

≤33400 |

≤135 |

|

Emission standards |

6-9 |

≤300 |

≤4 |

|

Actual effluent quality |

6.5-8 |

81 |

3.4 |

|

Removal rate |

- |

99.8% |

97.5% |

* pH is dimensionless, the unit of the rest are mg/L.