Printing and dyeing wastewater and its characteristics

Printing and dyeing Wastewater:

Printing and dyeing wastewater is discharged from printing and dyeing plants mainly focus on processing cotton, fiber, chemical fiber and blended textiles. It can be divided into 1 de-sizing wastewater, 2 kiering, wastewater 3 bleaching wastewater 4 mercerizing wastewater 5 dyeing wastewater 6 printing wastewater 7 finishing process wastewater 8 alkali reduction wastewater.

The features of printing and dyeing wastewater:

The pollutants in printing and dyeing wastewater are mainly dirt, salt, oil and grease on textile fibers such as cotton wool, as well as various pastes, dyes, surfactants, auxiliaries, acids, alkalis, etc. added during processing. The characteristics of textile industry sewage can be summarized as follows:

(1) Large amount of waste water, 2.5~3.5m3/100m fabric for printing and dyeing wastewater of pure cotton and blended textiles, 2-2.4m3/100m fabric for polyester-cotton fabric, 4-6m3/100m fabric for silk fabric, and 12-mesh fabric for fine wool fabric 15m3/100 fabric. The amount of wastewater is quite large.

(2) The water composition is complex and the wastewater contains residual dyes, slurries, auxiliaries, fiber impurities and inorganic salts. The nitro and amine compounds in the dye structure and heavy metals such as copper, chromium, zinc and arsenic have great biological toxicity.

(3) The printing and dyeing wastewater has high content of organic matter. The COD is adjusted to 800~1200mg/L. The composition of COD includes residual dyes, auxiliaries, slurry, etc. The COD of Alkali wastewater is up to 100g/L.

(4) The biodegradability is poor and the BOD/COD of wastewater is very low, generally around 0.2. Therefore, measures need to be taken to increase the B/C value to facilitate biochemical treatment.

(5) The wastewater contains a large number of auxiliaries and surfactants which not only makes it difficult to biodegrade and pollute the water, but also generates foam and hinders oxygenation during the biological treatment of aeration.

National Service Hotline:400-608-6866 Online

Conventional processes and limitations

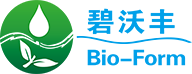

Hydrolysis Acidification-Biological Contact Oxidation- Process for Printing and Dyeing Wastewater with biochar

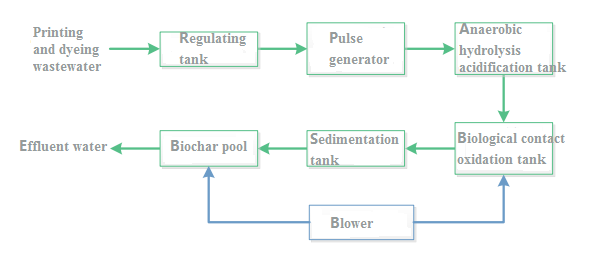

Combined process for printing and dyeing wastewater

Conventional process limitations

(1) The direct mixing of wastewater in each process makes the water quality complex and unstable

The wastewater of each process is relatively simple with single treatment object. For example, the de-sizing wastewater is mainly COD, the dyeing process wastewater is chroma and the bleaching wastewater is mainly residual bleach. If the wastewater of each process is directly mixed without pretreatment, the water quality becomes complicated and it will take more cost to treat diluted pollutants.

(2) "Biochemical regeneration", "flocculation and re-flocculation"

At present, most printing and dyeing enterprises in China generally adopt the technical method which is called “physicochemical-biochemical”, “physicochemical-biochemical-physical”, by increasing the flocculation and biochemical reaction time to increase the removal rate of COD, without combining their own water quality characteristics. As a result, the wastewater treatment project covers a large area with long process and high engineering costs but the treatment effect is still unsatisfactory.

(3) When the former materialization, the flocculant used is unreasonable

For the pre-physical treatment of wastewater with PTA as the main COD, the pH of the wastewater is between 4 and 5. Some printing and dyeing plants directly add a large amount of ferrous salt. However, it is not known that when the PH is lower than 7, a large amount of free divalent iron in the water will enter the biochemical in a dissolved state. After being taken into the aerobic tank, it will be oxidized into iron ions, making the water becomes red which wastes money and attribute to poor quality water.

(4) The old sewage treatment system cannot meet the demand of wastewater treatment after the upgrade of dyes and additives.

With the increasing market demand or product upgrading and the continuous improvement of the level of textile printing and dyeing technology, dyes and auxiliaries are continuously upgraded. The use of refractory industrial synthetic dyes and auxiliaries is increasing so that the biodegradability of printing and dyeing wastewater is significantly reduced and makes it more difficult to dispose. The original old sewage treatment process or ordinary microorganisms can’t meet the demand.

The advice for process improvement

(1) Conducting diversion pretreatment of wastewater

(2) Improving biochemistry

(3) Selecting highly efficient microbial strains

(4) Choosing a suitable filler

(5) Enhancing nitrogen and phosphorus removal

(6) Selecting a reasonable and correct flocculant

(7) Adopting summer cooling measures

Package product

Applications